BA/MA: Digital Twins-Based Predictive Maintenance for Forestry Machinery

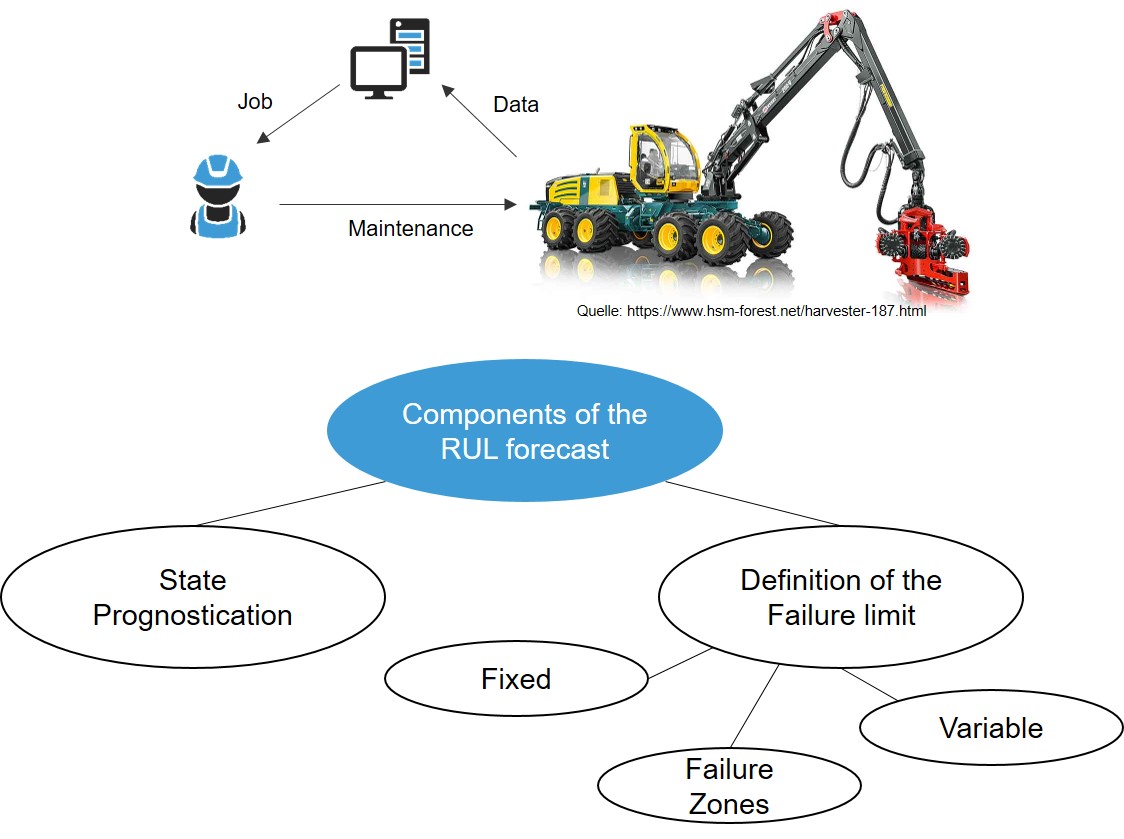

Today’s forestry machinery, such as harvesters, are usually capital-intensive. Keeping such machinery in optimal operational condition with highest availability and performance is viewed as a vital part of ensuring the return on investment. As a result, Predictive Maintenance has emerged as a maintenance strategy aimed at maximizing uptime by using data-driven predictions to identify when machinery needs maintenance stops. Furthermore, unexpected failures are prevented, which, depending on the component, also protects the environment or users.

Nevertheless, the development of Predictive Maintenance concepts encounters a wide range of challenges, both from the technical and organizational perspective. Technically, the collected data about machinery’s status demands interoperability and insight related to expert’s knowledge since they are captured from multiple sources. Additionally, individual machines of the same manufacturing model may operate differently under different conditions, leading to increased complexity of the data model. Organizationally, data security and privacy are always emphasized because data always implicates some sensitive information about process and business models.

In light of Industry 4.0, novel technologies, such as the Internet of Things and Digital Twins, facilitate the development of Predictive Maintenance by providing a foundation for, e.g., real-time data analysis, improved accuracy of data models, enhanced visibility while preventing data tampering and leakage.

In this work, an approach for developing Digital Twin-based Predictive Maintenance shall be conceptualized and prototypically implemented in an Edge device in order to monitor and analyze the battery and filter condition of a diesel engine in a forestry harvester. Combined with IoT technologies, this “Self-sovereign” Digital Twin [1] shall autonomously and securely handle data and requests. The result is to be tested in a virtual testbed.

This work is directly combined with a research project “Smart Forestry” [2] funded by Fachagentur Nachwachsende Rohstoffe (FNR) e.V. (Funding code: 2220NR254 A-H).

Concrete work packages include:

- Familiarization with Digital Twins and Internet of Things

- Literature research on Predictive Maintenance methods for the given data sets

- Development of a concept for combining Digital Twins and Predictive Maintenance

- Prototypical implementation of the developed concept

- Demonstration of the functionality using fictitious or real data in a virtual testbed

- Written elaboration and presentation

Keywords: Digital Twins, Predictive Maintenance, Internet of Things, Forestry Machinery

[1]: Weingaertner, T., & Camenzind, O. (2021). Identity of things: Applying concepts from self sovereign identity to IoT devices. The Journal of The British Blockchain Association.

[2]: https://www.kwh40.de/smartforestry/