With the rise of Industry 4.0, the integration and coordination of Digital Twins (DTs) has become a fundamental aspect of modern cyber-physical production systems. Each DT acts as the digital counterpart of a physical asset, and its structure, semantics, and behavior are standardized through the Asset Administration Shell (AAS). The AAS serves as the cornerstone of interoperability, enabling the discovery, invocation, and monitoring of services across industrial ecosystems.

To support real-world collaboration between such DTs, processes play a key role. Modeling and executing process behavior not only enables automation and flexibility, but also provides a clear and unified way to coordinate interaction among heterogeneous systems. While process execution engines and workflow systems are widely used in IT, their adoption in Industry 4.0 settings still lacks standardization— especially when human interaction and decentralized coordination must be included.

In this context, Business Process Model and Notation (BPMN 2.0) provides a suitable modeling language to define, communicate, and execute the behavior of Digital Twins in an understandable way. Especially in environments where both humans and autonomous Digital Twins are part of the execution and decision-making chain, BPMN can serve as a bridge between high-level orchestration and concrete AAS-based execution.

However, existing tooling and workflows for AAS-based process execution often neglect two key aspects:

- The modeling of Industry 4.0 processes based using standardized elements

-

The need for negotiation and coordination among multiple Digital Twins before a process can be executed.

-

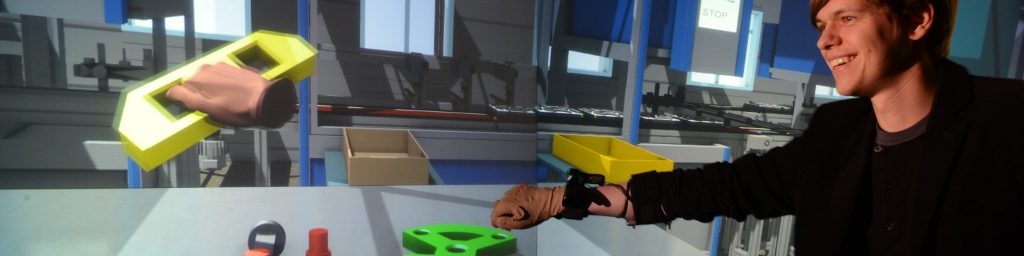

The integration of Human-Machine Interfaces (HMIs) for involving human actors in the loop, especially in cases where process approval or manual interaction is required.

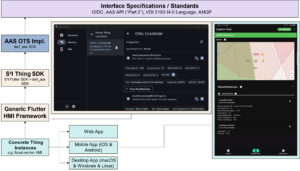

This thesis proposes a novel approach for collaborative, process-driven interaction in Industry 4.0 environments. A Flutter-based Human-Machine Interface (HMI) shall be developed that enables:

- the visual modeling of orchestrated and choreographed processes using BPMN 2.0,

-

the negotiation and confirmation of digital process contracts among multiple Digital Twins and HMIs,

-

the execution, and monitoring of process execution via AAS Submodels and Events.

To support this, an integration between Flutter and an existing JavaScript-based BPMN modeling tool will be implemented. Digital process contracts will be generated based on the modeled processes and distributed to all involved participants (Digital Twins or HMIs). Only once all actors confirm their participation, the process may begin.

Furthermore, each participating Digital Twin will receive execution instructions via AAS Submodel updates. Human actors, when involved, will interact through their respective HMIs, which are able to render the process steps assigned to them and issue confirmations. The system will allow any participant to observe the live state of a process if the corresponding AAS Submodel is accessible and Event messages are received.

This approach demonstrates how the standardized infrastructure of the AAS can be extended to support negotiation, coordination, execution, and monitoring of interactive processes, while offering an intuitive and user-friendly interface for both technical and non-technical users.

Key tasks include:

-

Embedding an existing BPMN modeler (bpmn-js) in a Flutter-based application

-

Designing concept for digital contracts in Industry 4.0 workflows

-

Defining and implementing new message types for the interaction

-

Monitoring and visualizing process states via AAS events

-

Extending the AAS data model with process-related submodels

-

Implementing a distributed contract and execution mechanism

-

Integrating implementations into a existing Flutter based HMI

Supervisor: Bektas